The Differences Between Air-Cooled & Water-Cooled Chillers

Before going into a debate about which is better, water-cooled or air-cooled chiller. We should know what a chiller is?

Describe a chiller

A chiller is an appliance that employs a cooling system to transfer the heat from a source and redistribute it to the outside surroundings. This heat exchange mechanism is the primary cooling system in power generation and other industrial buildings. It is merely a unit of ethanol storage and elements for water movement.

The equipment that reduces temperature while extracting heat receives a continuous flow of coolant from the storage. Furthermore, chillers that spread warmth through blowers are air-cooled. These are more prevalent in power generation and more contemporary. We compare the two technologies in this post, and it’s up to users to decide which one to use. However, as India’s biggest chiller manufacturer company, Reynold India will assist in making a preferable choice according to your aspiration.

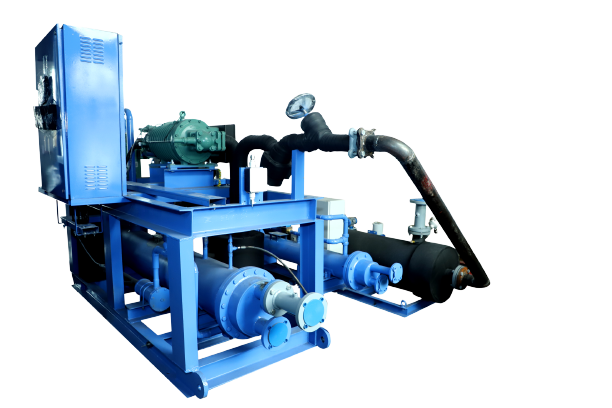

A Synopsis Of Water Cooled Chiller.

Because they have a cooling system, water-cooled chiller units are highly productive than air-cooled ones.

Due to e air temperatures lamp degree, which is lesser than that of the arid tuber surroundings, affects whether water begins to condense, water-cooled chillers seem more useful. A chiller is extremely efficient the deeper it crystallizes.

Several crucial parts to this system, such as:

- Thermal energy Storage tank

- Chiller

- Towers for cooling

- Compressors for condenser water

- Blowers for product water

- Condenser water pumps

What Advantages Can Water-Cooled Chillers Offer?

Water-cooled chillers take up less space than air-cooled chillers, which is why many clients invest in water-cooled chillers instead of an air-cooled chiller. In addition to being more efficient and durable than an air-cooled chiller, it also has a higher turnover rate. The water-cooled equipment might appeal to those who want the device to be used inside.

Describe An Air-Cooled Chiller.

The air-cooled chiller is used wherever visual, ecological, or water usage limitations apply. Two very different water-cooled and air-cooled chillers rely on airflow to heat energy exchange.

Typically, water-cooled chillers are more affordable and effective but also use a lot of water.

Since air-cooled systems don’t need cooling systems, condensing pumping stations, or other related Ventilation equipment, their starting price is less than that of water-cooled devices.

The air-cooled chillers employ an air pressure stream, but the water-cooled chillers use a saturated airflow instead of the cooling systems.

Evaluating The Comparison Between Air-Cooled Choler And Water Chiller

Efficiency

With an aluminum blade style condensation, the efficient Water-cooled chiller can release temperature into the surrounding air. Eventually, the airflow evaporates the heating.

The core benefit of water is that it has more heat transfer features than air. Membrane elasticity regulates thermal flow with continuous fluctuation in location temperature.

Water-cooled chillers typically use cylindrical or shell condensers. During condensation, a liquid enters and exits the chiller unit, eliminating the heat. Due to water’s superior heat exchanging properties, many companies and plants use water-cooled chillers.

Since the additional needs for water filtration and servicing are investment demanding and won’t be instantly offset by the reduced production expenses, micro installations are usually air-cooled. Water is most frequently employed to chill bigger Ventilation water chillers. Ventilation experts and personnel appreciate the technology that requires little to no servicing.

Price

The price of an air-cooled chiller is higher per unit than that of a water-chiller.

Placement

The area must be free and dehydrated for the vented heat from an air-cooled chiller to escape. If warm air is available, productivity will gradually decline, and the chiller may halt. In contrast, a water-cooled chiller has less need for airflow since the water dissipates the hot temperature.

Dimension

The air-cooled chiller’s condenser is huge because it necessitates a bigger metal blade space for warm temperature distribution and blowers to create ventilation. However, a water-cooled condenser can complete the equal heat exchange function while being considerably shorter.

The condensation device’s size influences the difference between an air-cooled chiller and a water-cooled chiller.

Connection and pipework

You only need to complete the plumbing between the air-cooled chiller and the cooling unit.

The two extra prerequisites for a water-cooled chiller are installing a refrigeration system and the interconnection of the chiller condensing to the cooling system.

Servicing and maintenance

The lack of maintenance or poor servicing can cause chiller efficiency to decline. Therefore, wiping out the condenser is vital because the heat transfer surface of a grimy condensation unit will significantly reduce chiller effectiveness. Ensure to conduct periodic maintenance and service for your chiller.

Conclusion We have explained the major differences, qualities and other significant aspects of water and air-cooled chillers. It becomes hard to select anyone of them. However, users can choose them according to their financial capacity, price, placement, space available, maintenance cost and other factors mentioned in the above section. Follow Us